In industries such as petroleum, chemical, and power, level gauges are key components for ensuring the safe operation of equipment. As the core component of level gauges, transparent & flat glass level gauges have become the preferred choice for many enterprises due to their excellent corrosion resistance and high transparency. This article will provide a detailed introduction to the characteristics, application scenarios, and main differences between transparent gauge glass and reflex gauge glass.

Characteristics and Advantages of Transparent Liquid Level Gauge Glass

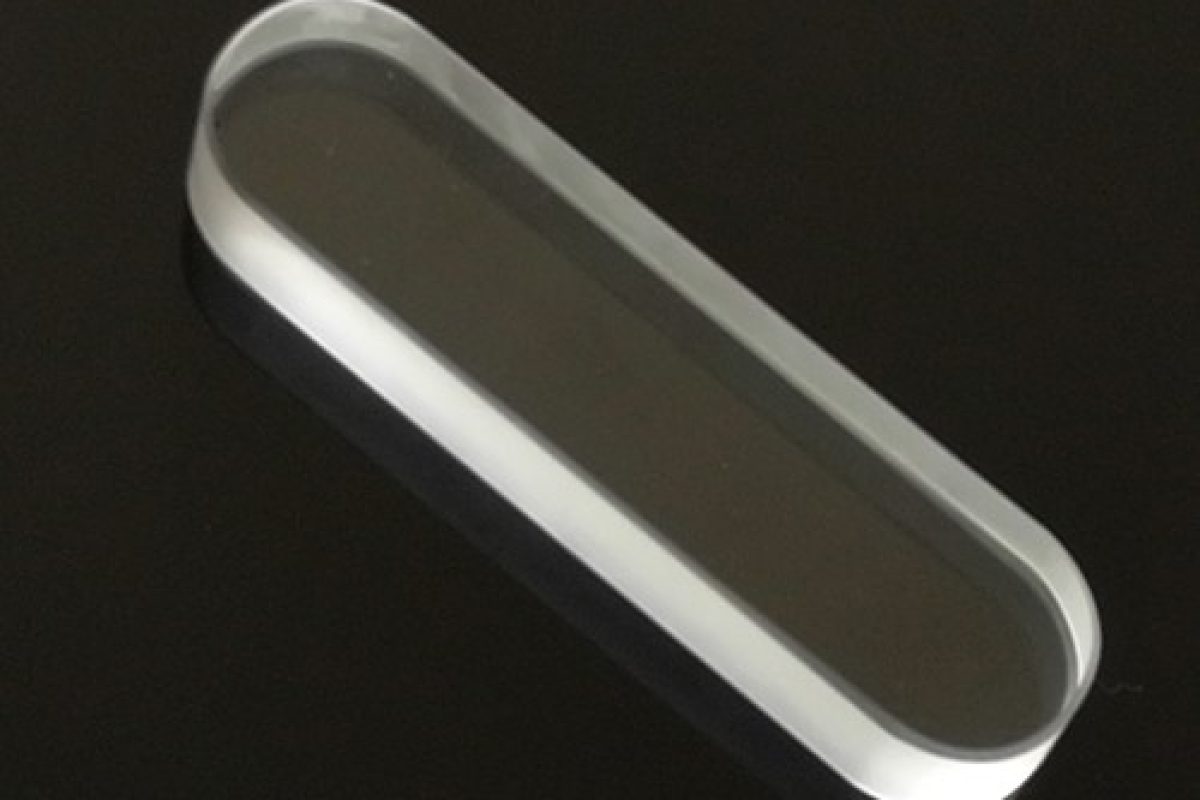

Transparent liquid level gauge glass is made of high borosilicate glass or quartz glass, after precision processing and heat treatment, it has the following outstanding characteristics:

- High transparency: smooth surface without lines, light transmittance up to 90% or more, easy to directly observe the liquid level changes.

- Strong corrosion resistance: it can withstand acid, alkali, organic solvents and other corrosive media, suitable for chemical industry, pharmaceutical and other harsh environments.

- High-temperature and high-pressure resistance: some products can withstand high temperatures above 400℃ and pressures above 10MPa, with excellent stability.

- Simple structure: flat plate design without grooves, not easy to accumulate impurities, cleaning and maintenance is more convenient.

Application Areas:

Widely used in petroleum storage tanks, boiler steam packages, chemical reactors, food processing equipment and other scenarios that require high-precision liquid level monitoring.

The key difference between transparent gauge glass vs. reflex gauge glass

- Structural design:

Transparent gauge glass is completely smooth flat plate, light refraction is uniform;

Reflex gauge glass has vertical grooves engraved on the surface, which magnify the liquid surface through refraction to improve visibility.

- Applicable media:

transparent gauge glass is more suitable for clean liquids (such as water, oil);

reflex gauge glass is commonly used in high-viscosity or easy to wall medium (such as asphalt, slurry).

- Maintenance requirements:

transparent gauge glass is not easy to leave dirt, easy to clean;

reflex gauge glass grooves may accumulate impurities, need to be cleaned regularly.

- Pressure difference:

transparent gauge glass has a smooth surface and simple structure, strong pressure resistance;

reflex gauge glass due to special groove processing, pressure resistance is not as good as transparent gauge glass.

A petrochemical enterprise equipment engineer said: “in the corrosive acidic liquid monitoring, transparent gauge glass corrosion resistance and long-term stability outstanding performance. Reflex gauge glass is more suitable for viscous liquids and low light conditions, enterprises need to choose the appropriate model according to the characteristics of the medium.”

With the development of industrial automation, the performance requirements of level gauge glass are increasing. Transparent liquid level gauge glass will continue to occupy an important position in the field of clean liquid monitoring by virtue of its reliability and economy. Enterprises need to combine the media characteristics, environmental pressure and other factors to choose the optimal solution.