Reflex glass level gauge is as known as reflex level gauge and prismatic level gauge, are commonly used to detect the level of liquids in containers. The operating principle of reflex glass level gauges is based on the laws of refraction and reflection of light.

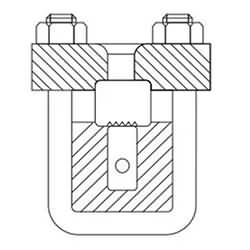

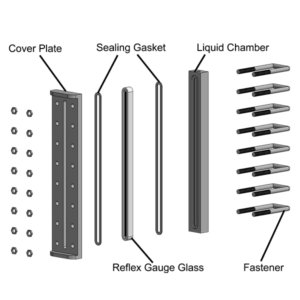

The core component of a reflex glass level gauge is one or more reflective level gauge glasses. One of them has a groove on its surface with a cross-section angle of 90° and is mounted towards the chamber. When the level gauge is in operation, the upper part of the chamber is filled with gas and the lower part with liquid, and the liquid level can be clearly seen by the different brightness of the glass in the liquid zone and in the gas/vapor zone. Reflex glass level gauges do not require specific illumination: ambient light during the day is sufficient.

To avoid leakage in case of glass breakage, a safety ball check is usually fitted to the cross-connectors or shut-off valves.

Reflex glass level gauges are suitable for most situations and have the advantages of low initial cost, low operating cost, easy level reading and no need for a power supply.

Product Features

- Simple installationand maintenance.

- Does not require electricity to operate. Still works in the event of a power outage.

- Directly observe the liquid level position-no calibration is necessary.

- It has a quick shut-off device for vapor and liquid leakage;

- 5. Low maintenance costs;

Suitable for steam media up to 40 bar and process media up to 400 bar

| Specification of Reflex Glass Level Gauges | |

| Center to center distance | 300–3600 mm |

| Visible Length | 95-3360mm |

| Body Material | Carbon Steel; Titanium alloy; Stainless Steel 304/316L |

| Operating Temperature | -20 °C to +450 °C |

| Working pressure | 40bar |

| Gauge Glass Material | Borosilicate glass ; Aluminosilicate glass |

| Glass Size | A1-A9 ; B1-B9 |

| Gasket Type | Graphite composite gasket;

non-Asbestos gasket; PTFE gasket; |

| Way of Connection | Flange; Thread |

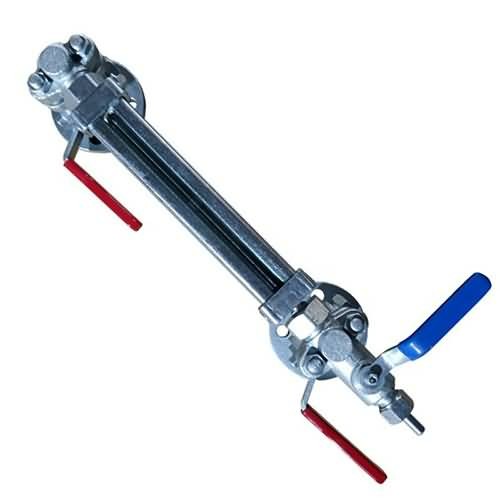

One-section reflex level gauge

One-section reflex level gauge

Multiple-section reflex level gauge

Multiple-section reflex level gauge

Why use reflex glass gauge

Reflex glass level gauges have been in use for over 100 years. They give you the ability to directly view the process fluid under temperature/pressure conditions that would render most other level technologies useless.Their construction is very robust, and reliable. They define the term “simple to use”. After installation, the only tool you will need is your eyes. Reflex glass level gauges are relatively inexpensive as compared to most other level technologies.

Please provide the following parameters when ordering:

- Model specification;

- The name of the measured medium, such as: water, gasoline, kerosene and so on. Medium density, if you do not know the density, you can tell us the name of the medium, mixed liquids to know which liquids are composed of;

- Measuring range of the instrument: the center distance of the two flanges;

- Operating pressure: the highest withstand pressure;

- Operating temperature: the minimum and maximum temperature of the measuring liquid;

- Material requirements: such as: SS304, 316L, carbon steel, if you do not know which material, you can ask us (we will choose different materials according to different media);

- Whether supporting the supply of flanges, bolts, nuts, valves, sealing washers and other accessories;

- Flange standard: the nominal diameter of the flange, the more widely used flange is DN20 or DN25;

- Special requirements: please specify in detail before ordering, such as whether to take the remote transmission, thermal insulation jacket and so on.