In modern industrial processes—whether in energy and chemical engineering, pharmaceuticals and food production, or water treatment—level gauges serve as the “eyes” monitoring the liquid levels of media within storage tanks and pipelines. Their stability and reliability directly impact production safety, efficiency, and environmental protection. However, discussions about level gauge performance often focus on their main structures, sensors, or display systems, while overlooking a tiny yet crucial component—the sealing gasket. This article delves into how this seemingly “unremarkable” element becomes the unsung hero ensuring the safe operation of level gauges.

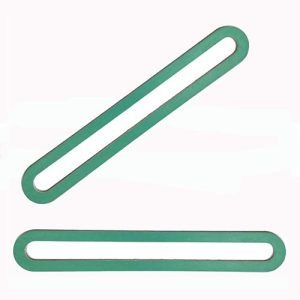

Seal gaskets are installed at the sight glass, flange connections, or process connections of level gauges, serving as a robust and reliable sealing barrier. This barrier fulfills three critical functions:

Preventing Media Leakage: The media measured by level gauges may be corrosive, flammable, explosive, toxic, or highly valuable. A high-quality sealing gasket effectively seals interface gaps, ensuring the media remains securely contained within the system. This prevents safety incidents, environmental pollution, and property damage caused by leaks.

Blocking external contamination: In industrial environments filled with dust, moisture, or corrosive gases, the seal effectively prevents external contaminants from entering the level gauge. This protects precision components from contamination and corrosion, ensuring clear and accurate level indication while extending equipment lifespan.

Maintaining system pressure: For level gauges used in pressurized vessels, the seal must withstand the system’s operating pressure. It prevents pressure loss, safeguarding the integrity and stability of the entire pressure vessel system.

The Severe Consequences of Improper Selection: Safety Risks Cannot Be Underestimated

“Seal gaskets may be small, but their selection and installation involve significant expertise,” stated a senior equipment engineer. “Incorrect selection can lead to catastrophic consequences.”

Using gaskets incompatible with the measured medium, insufficient in temperature or pressure rating, or already aged can cause minor “leaks, spills, drips, and seepage” at best. This compromises the cleanliness of the production environment and wastes materials. In severe cases, seal failure could trigger massive leaks of hazardous materials, leading to major safety incidents like fires, explosions, or personnel poisoning. Additionally, seal failure may cause inaccurate level gauge readings, providing operators with erroneous information that could trigger misoperations and threaten the entire production system’s safety.

Advancements in materials science have significantly enhanced gasket performance. Common gasket materials currently available on the market include:

Asbestos-Free Rubber Gaskets: Offering excellent elasticity and sealing properties, suitable for a wide range of general-purpose applications.

Polytetrafluoroethylene (PTFE): Renowned for its exceptional chemical resistance and broad temperature tolerance range.

Graphite Gaskets: Manufactured from pure compressed graphite or composite materials combining graphite with metal sheets or wires. Ideal for demanding high-temperature and high-pressure conditions.

When selecting gaskets, comprehensive consideration must be given to the chemical properties of the medium, operating temperature, system pressure, and the configuration of the mating surfaces. An increasing number of level gauge manufacturers and users are prioritizing customized gasket solutions to ensure optimal compatibility with specific application scenarios.

In summary, while a sealing gasket is a minute component within a level gauge, its role is far from negligible. It serves as the cornerstone for ensuring leak-free, long-term, safe, and stable equipment operation. In today’s pursuit of industrial automation and intelligence, we must pay greater attention to the quality and selection of these fundamental components. True excellence lies in the details—fortifying the defense of safe production from its very source. The next time you inspect or maintain a level gauge, don’t forget to acknowledge this unsung “guardian of safety.”