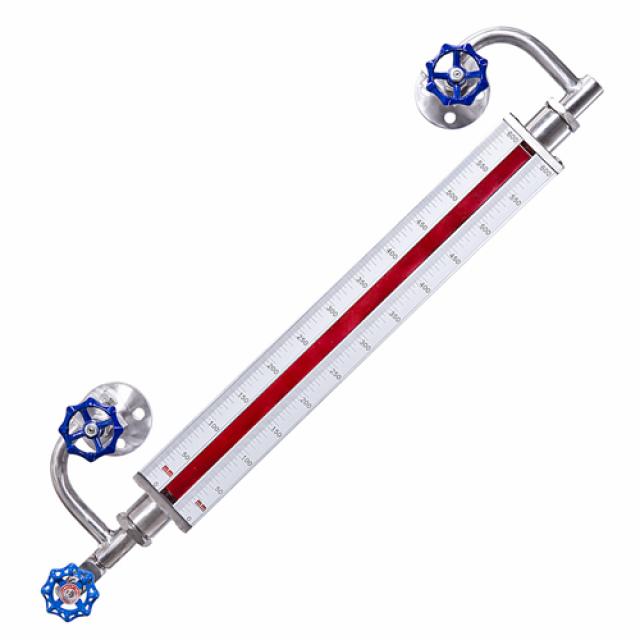

Straight-Through Tubular Liquid Level Gauge is a kind of sight glass level gauge that can show the liquid level directly. It is also called I-Type Oil Level Gauge, I-Type Single Connector Glass Tube Liquid Level Gauge. It is a small type glass tube level gauge that combines the advantages of glass tube level gauge, plate level gauge and boiler level gauge, and overcomes the weaknesses of the original glass tube level gauge, such as the fear of breakage, not stable, unsafe, not pressure resistant, unclear display, and low working temperature and so on. To a certain extent, it can replace glass plate level gauges and is cheaper than level gauges with the same characteristics.This type of level gauge is widely used in boiler steam water level, tank level in chemical industry or petroleum field etc.

Product Features

- Simple installation and maintenance.

- Operate without electricity. Can still work in case of power failure.

- Directly observe the liquid level position without calibration.

- Low price.

- Sturdy and durable;

| Specification of Straight-Through Tubular Liquid Level Gauge | |

| Measurement range | 0~1000mm |

| Body Material | stainless steel 304, 316, brass, carbon steel; |

| Operating Temperature | -10 °C to +180 °C; |

| Working pressure | 1.0 MPa; |

| Glass Tube Material | borosilicate glass; quartz glass tube |

| Thread standard | G; ZG; BSP; BSPP; BSPT;NPT; |

| Way of Connection | thread |

Why use glass level gauge

Glass level gauges have been in use for over 100 years. They give you the ability to directly view the process fluid under temperature/pressure conditions that would render most other level technologies useless.Their construction is very robust, and reliable. They define the term “simple to use”. After installation, the only tool you will need is your eyes. Glass level gauges are relatively inexpensive as compared to most other level technologies.

Please provide the following parameters when ordering:

- Model specification;

- The name of the medium to be measured, such as: water, petrol, paraffin, etc..

- Material requirements: e.g. SS304, 316L, carbon steel;

- Connection: flange or thread;

- Flange standard: nominal diameter of the flange, currently used more DN20 or DN25 flange;

- Measuring range of the instrument: the centre distance of two flanges;

- Material of glass tube, diameter, length, wall thickness;

- Working pressure: the highest withstand pressure;

- Working temperature: minimum and maximum temperature of the measuring liquid;

- Special requirements: please explain in detail before ordering, such as whether to take the remote transmission, thermal insulation jacket and so on.