Glass tube oil level gauge is consists of two parts: the outer metal protective shell and the inner glass tube for liquid measurement. It is connected to the tank by thread at any position, and is usually used for liquid level measurement of oil tanks in the petroleum industry。

The metal shell of glass tube oil level gauge protects the inner glass tube from damage without affecting the effect of visual observation. Meanwhile, it overcomes the weakness of general tubular level gauges, such as fragile, unstable, and unsafe.It combines the multiple advantages of glass tubular level gauges, planar level gauges and boiler level indicators. It can replace planar level gauges to some extent due to its low costs than that of planar level gauges of the same properties.

Product Features

- Robust structure. The glass tube for measurement is covered with a metal protective shell to prevent the glass tube from being broken by accidents.

- Direct observation. The gauge glass of oil level indicator can achieve the best level observation effect, and its transparency can be used to observe the condition and color of the liquid.

- Simple structure, easy maintenance.

- Excellent corrosion resistance, high temperature resistance and inexpensive price.

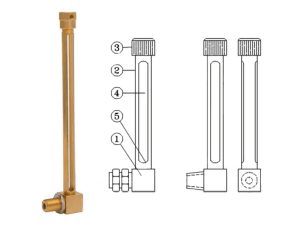

Glass tube oil level gauge structure diagram

- Body

- Protect pipe

- Nut

- Tube (Glass)

- Seal/Gasket

| Specification of Oil Level Indicators | |

| Range of Measurement | 0–1000 mm |

| Operating Pressure | 0.6–1.0 MPa |

| Operating Temperature | -10 °C to +180 °C |

| Body Material | ss304, ss316, brass, carbon steel |

| Gauge Glass Material | Glass |

| Way of Connection | Threaded connection |